Existing lightweight materials (expanded polystyrene sandwiched between steel panels, wood-plastic composites and high-performance concrete with polymeric blends) create fire hazards due to the high flammability of the embedded polymers. Novel strategies to combine nanoparticles with existing flame retardants through nano-filter technology have the ability to effectively control the thermal degradation process and significantly enhance the flame retardant properties of polymers. Recently, studies on the use of bio-inspired flame retardants such as polydopamine, bio-macromolecules proteins (whey proteins, caseins, hydrophobins) and deoxyribonucleic acid (DNA) on test samples have demonstrated remarkable flame retardant or even flame suppressant features. Within this Training Centre, the critical challenge is to investigate appropriate processing techniques to up-scale this new nanotechnology and bio-inspired flame retardants to produce novel eco-friendly and durable fire retardants.

Bio-inspired flame-retardant render techniques

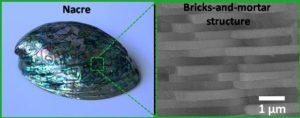

Additionally, with our current work, it is also found that bio-inspired technologies are effective methods to impart the high flammability polymers with excellent fire safety performances. It is found that nacre’s bricks-and-mortar structure, consisting of layers of organic and inorganic materials such as 2D calcium carbonate enables it with extraordinary mechanical and flame retardancy. Hence, a nacre-mimic coating technique called layer-by-layer (LbL) assembly was developed and adopted to impart the high fire risks polymers with well-performed flame retardants.

The fundamental concept of LbL assembly involves the arrangement of oppositely charged materials as multiple bilayers (BLs). The LbL deposition involves the surface activation, substrate immersion and a drying process after the desired numbers of BLs were obtained. Finally, the bio-inspired hybrid (organic/inorganic) flame retardant coated polymers were fabricated.

Consequently, with the nacre inspired idea, we performed a flame-retardant coating to one of the high flammability polymers namely polyurethane foams (PUFs) via this bio-inspired surface modification method. Chitosan, an organic material extracted from shrimp shell, and a 2D ultrathin nanomaterial called titanium carbide was selected.