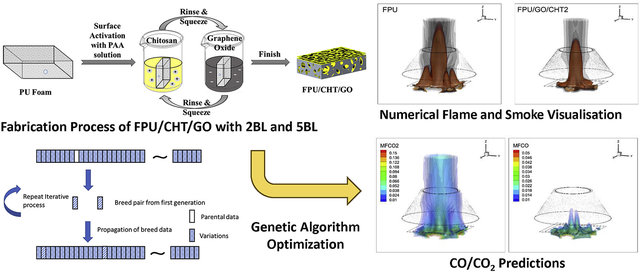

Inspired by the advanment of repid development in “machine learning” techniques, we now proposed using genetic algorithm theory to optimise the pyrolysis kinetics input data of any polymer composites for our fire field models (i.e. computational fluid dynamics based). Typically, pyrolysis kinetics is extracted via thermal gravemetry (TGA), where the solid decomposition is studied in the format of Arrhenius chemical reactions. Herein, serveral key parameters including pre-exponential factor, activation energy, fractional variable of the reactions, exponential factor are required to be optimised for quality input data. Our pervious work has demonstrated with a simple hand-calculation, then followed by curve-fitting procedures, we can establish data with reasonable accuray prediction of small-scale flame for enigineered wood products. Now, we have improved the kinetics search with a fully automated iterative procedure utilising genetic search algorithms. This also greatly improve the accuracy of the prediction accuracy of our fire models.

More details can be find in the following links:

Also visit our page on ResearchGate to follow our updates: