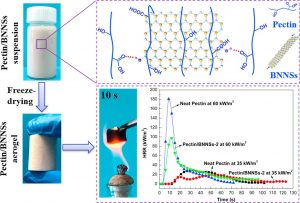

Recent advancement of bio-based aerogels has shown large potential as an absorbent material for resolving the global crude oil leakage issue. Owing to the bio-degradable features, these materials causes less damage to the ocean ecosystem while can effectively remove the oil pollution. A good example of bio-based aerogel material is pectin, which is an organic material extracted from apples. Nevertheless, flammability of pectin-based aerogel has always been a critical issue limiting its practical use in the industry. The latest work in the group has demonstrated that using Boron nitride nanosheets (BNNSs) will strengthen up the thermal stability, compressive strength and flame retardant properties of pectin (see figure below).

In this work, BNNSs were prepared via the exfoliation of hexagonal boron nitride in isopropyl alcohol. Extremely stable BNNSs dispersions were obtained after the ultrasonication in pectin aqueous suspensions, and the bio-composite aerogels were fabricated via the freeze-drying process. The digital photographs of pectin/BNNSs aqueous suspensions and Fourier-transform infrared spectroscopy results showed that there was a strong interfacial interaction between BNNSs and pectin macromolecular chains. Owing to the excellent dispersion and intensive interaction, the thermal stability, compressive strength and flame retardant properties of pectin/BNNSs bio-composite aerogels were significantly improved. Compared to neat pectin aerogel, pectin/BNNSs-2 (mass ratio of pectin and BNNSs, 10/1) possessed improved onset thermal decomposition temperature (by 9 °C), enhanced compressive strength (by 119%), reduced peak heat release rate (by 45%) and peak CO2 production (by 53%) at cone radiation intensity of 60 kW/m2. Residue analysis indicated that the presence of BNNSs promoted the carbonization of pectin aerogels.

More details can be find in the following link:

Also visit our page on ResearchGate to follow our updates: